From Device to Dashboard: Managing the "Fence Problem"

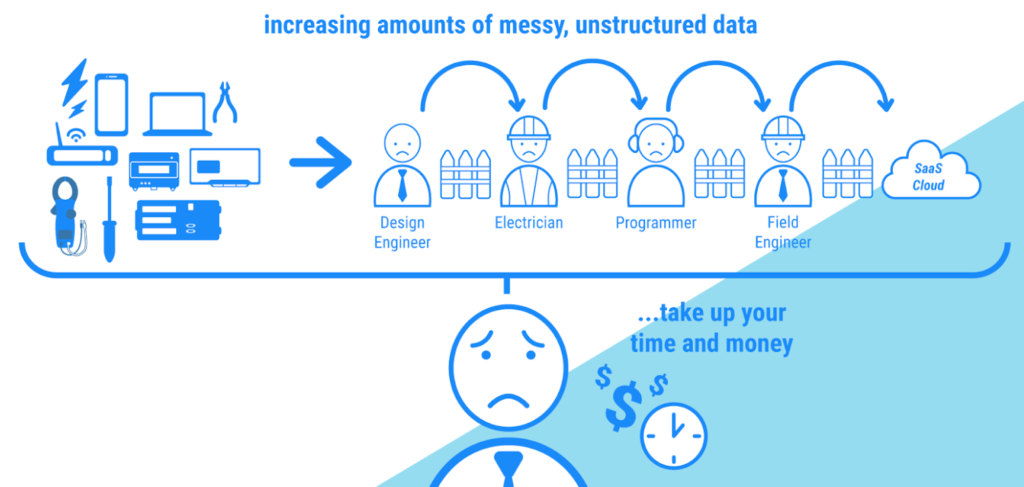

The path to getting good data can be a long, ugly and expensive one filled with many pitfalls, trials and tribulations. Behind the scenes you have a number of professionals that need to come together to collect, transmit and manage data before it ends up in a database ready to be used.

Proper coordination of design engineers, electricians/field technicians, device programmers and field engineers is critical for collecting data you can trust. The design engineer comes up with a solution and specifies options, electricians install hardware in the field, programmers configure the devices and map everything into the database and field engineers commission the system to verify everything is working as designed.

Sometimes the specialized work of all four roles is performed by a dedicated team of people working at the same company, or on the other extreme, all work is done by the same person. In most cases, much of the work is outsourced and goes back and forth between consultants and third-party service providers, leaving the owner in the dark.

What has been consistent over the last decade in the monitoring of PV power plants, storage systems and advanced manufacturing applications is the ‘fence problem’. Let’s review the workflow with details. Design engineering is left to pre-packaged systems from a single vendor because of lack of interoperability. Electricians install hardware in the field without site-specific documentation or contact with designers when things don’t look right. Programmers configure the devices from multiple vendors using different styles and map everything into the database multiple times. Finally, field engineers spend valuable time tracking down details when things don’t look right.

The fence problem is where things get “thrown over the fence”, as the project transitions from one professional to the next. The higher the fence, the higher the total project cost and the longer it takes to complete. Key questions to consider that determine the height of these fences include:

- Who is responsible for making sure that design and as-built documentation for devices collecting data is complete and accurate?

- Is there training and support for the electrician to properly install these devices?

- Who is managing the device configuration files for full transparency into the device setup?

- Are the configured files backed up in case the device needs to be replaced or audited over the project lifetime?

- Is the source for database mapping left a chance for the programmer to figure out?

- Who does the field engineer call when things aren’t looking right?

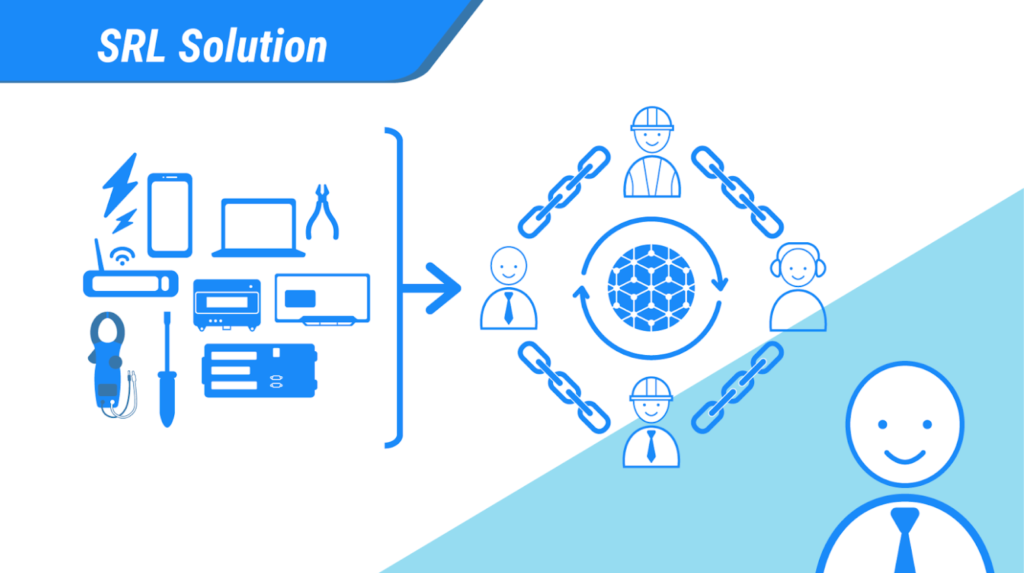

The fence problem is solved by proper process and project management. The traditional way to do this is to hire a dedicated project manager with deep domain expertise to manage the entire process. Smart Resource Labs has spent 5 years digitizing this process and building a platform to lower costs by managing devices and fences. If you have questions about how your team can benefit from our one point of contact, end-to-end data management services, call Smart Resource Labs to get site specific recommendations from a professional.